Engineering design

Form of Engineering Design

Basic Engineering Design

Definition

Basic Engineering Design includes simulation of process using adequate tools upon a careful analysis of requirements. This gives you an early view of various steps, activities, and events participating in a process. During process design and engineering, we consider physical properties of materials and constrains associated with the process under question.

Scope of Works

Due to the uniqueness of each project, a certain project will be has a specific scope of works. In Basic Engineering Design, the scope of works may include, but not limited to: conceptual process studies (material balances, process flow sheets); preliminary plot plan; definition and sizing of main equipment resulting in process specifications; specification of effluents; definition of control and safety devices; generally speaking, all basic studies required to support Basic Engineering Design Package (BEDP) containing all data needed by a competent contractor to perform the Detail Engineering.

Ref: Technip

Front End Engineering Design

Definition

Front End Engineering Design comes after the conceptual design or Feasibility Study or Basic Engineering Design. Front End Engineering Design focuses the technical requirements as well as rough investment cost for the project. Front End Engineering Design can be divided into separate packages covering different portions of the project. Front End Engineering Design package is used as the basis for bidding the Execution Phase Contracts (EPC, EPCI, etc.) and is used as the design basis.

Scope of Works

Include determining the material and energy balance, project charter; doing preliminary design of equipment, layout, schedule, cost estimate; specifying the purchase-ready major equipment, project execution plan, preliminary 3D model, electrical equipment list, line list. Frequently, safety-related sudies (HAZOP, HAZID) is included in Front End Engineering Design package as well.

Detailed Engineering Design

Definition

Detailed Engineering Design follows a process which entails conceptual design, embodiment design and detailed design. And when they performed professionally, eventually results in a well designed solution.

Phase one of Detailed Engineering Design is conceptual design which drawings are the main output. The drawings produced are often quite simple ideas with little detail, but the aim of the conceptual design is to commit ideas to paper.

Phase two of Detailed Engineering Design is embodiment design which starts with the concept and develops it into a workable system that can be further developed. During this phase, engineers will typically follow a framework of clarity, simplicity, and safety in achieving the design goal.

Phase three of Detailed Engineering Design is detailed design where the design is refined and planed, specification, and estimations are created. Detailed design will include outputs such as 2D and 3D models, P&ID’s cost build up estimations, procurement plans, etc. This phase is where the full cost of the project is identified.

Ref: www.projen.co.uk

Scope of Works

- Purchasing of equipment, main and bulk.

- Thermal rating of heat exchangers.

- Development of piping and instrumentation diagrams release for construction.

- Development of detailed piping drawings, including isometrics and stress calculations.

- Development of detailed drawings related to instrumentation, electrical facilities and civil works.

- Management of vendor drawings.

- Cost and schedule control.

- Start-up procedures.

Ref: Technip

Related Projects

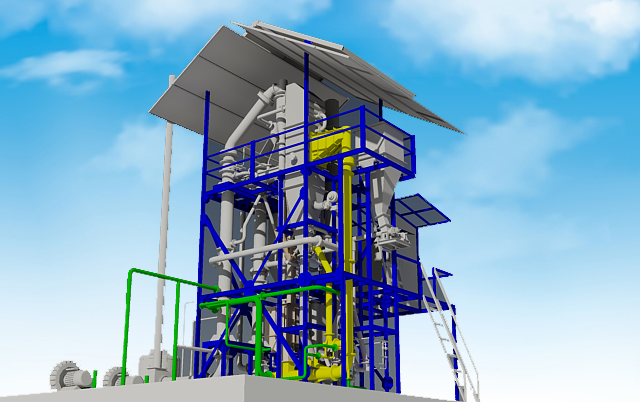

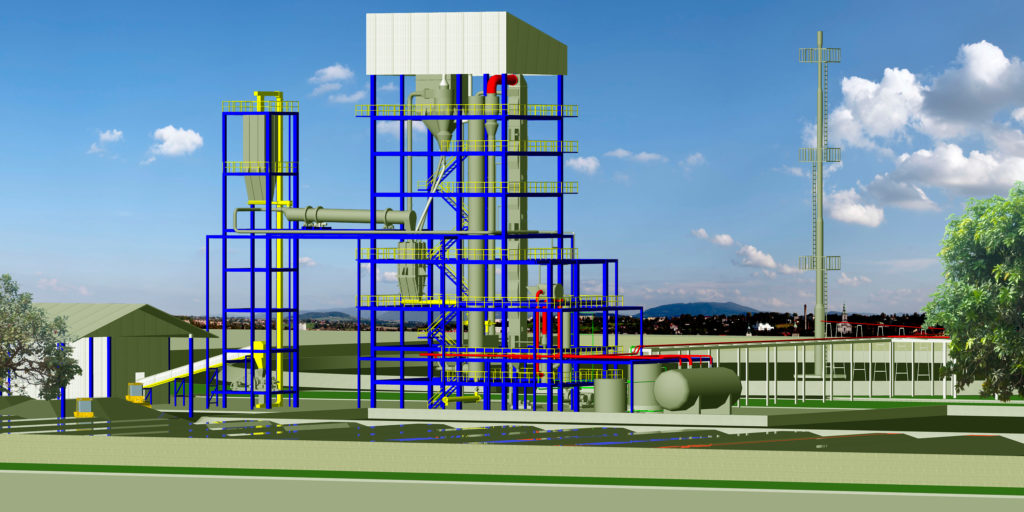

Feasibility Study and Basic Design of Lignite Gasification in Kotabaru, Kalimantan Selatan

Front End Engineering Design of Lignite Gasification in Kotabaru, Kalimantan Selatan